Of lawnmowers, snow and cake

|

| The journey to work: no wonder everyone we met was so happy |

Warmth, hospitality, passion - three words which sum up my recent visit to the Viking factory in Austria. Oh, and let's not forget lawnmowers, snow and cake ;)

I've always found factory visits fascinating and this one was exceptional. It was also enough to make NAH green with envy - more on that later.

|

| The view from the Viking factory car park - a 'pinch me, I'm really here' moment |

You may wonder why anyone would want to work in a factory in the midst of such beauty. Well, it turns out peak production time (January, February) coincides with when the locals can't work on their farms.

It means an extra income for them which also helps preserve the traditional Tyrolean way of life. Besides seeing the passion for their work, pride for their region also shone through during our visit.

|

| The factory in Kufstein, with a couple of products undergoing extreme testing in the -14oC temperature ;) |

Sadly I couldn't take photos inside the factory and I probably would have forgotten anyway as the process was so absorbing. It's probably the cleanest and quietest factory I've ever visited; even the many forklift trucks dancing their way along the factory floor were quiet. The drivers' sideways position in the cab meant they could keep a good eye out and easily avoid any collisions.

We were shown the assembly line where components from all over Europe and beyond come together to make the final product. They were assembling some of the 4 Series mowers whilst we were there i.e. the mid-range ones, plus STIHL's compact cordless blowers like the one I reviewed last year.

There are 4 stages in the process with quality checks made before the work is accepted by the next person in line. Final tests at the end of assembly include a final check once the product is inside its delivery box, where any discrepancy in weight means something e.g. the instruction booklet has been left out.

We learned there are some quirky regional differences. In Scandinavia they go for mulching in a big way, the Germans like to scarify, and the French like tilling. And we Brits? We prefer a much closer

|

| Part of the Viking range we saw on show at the factory |

Engineering in action

I used to love testing to destruction in my previous IT jobs and it was good to see this concept also in action at Viking in a more physical form. Their engineers conduct around 60 different product tests and we were shown three of them.

The first started with a demonstration of a computer model of a lawnmower blade which could be modified to see which design is best for minimising damage when the blade hits a solid object. This has the potential to damage not only the blade, but also the central crankshaft and ultimately the engine. It would be costly to repair, if not a complete write-off of the machine.

They've found that by adding a 'wave' to the blade, not only is damage eliminated or minimised, it's also resulted in a quieter machine and increased efficiency so that battery life is extended - three improvements for the price of one. We were then shown an actual machine test - one of hundreds - which also supplies the data needed to refine the computer model.

The second test also involved the blade, and was a resonance test. This reveals the frequencies which put the most stress on the blade and so should be avoided when the machine is running. It was amazing to see a thick metal blade suddenly flap its 'wings' like a bird when the 'right' frequency range was reached.

|

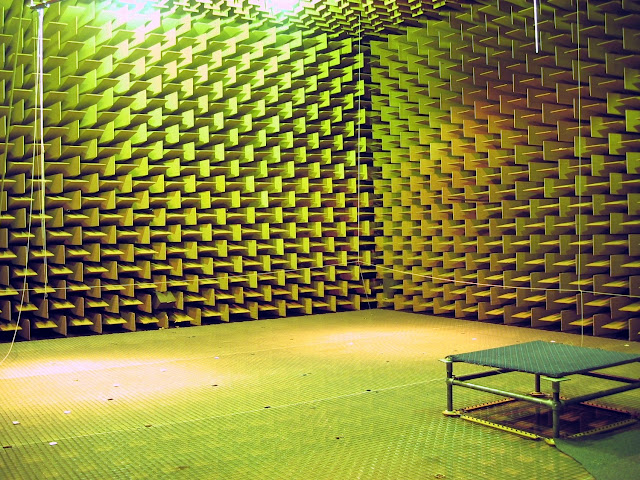

| Anechoic room at the Technical University of Denmark. Credit: Arnaud Dessain via Wikimedia Commons |

The sound of silence

Finally, we were led into an anechoic chamber similar to the one pictured. There aren't that many of these around in the world, so to experience a place designed to minimise sound was something special and most striking. NAH tells me they can't be completely silent, but they come close. He's also quite envious I've been in one when he - the engineer and Hi-Fi addict - hasn't.

Viking's anechoic chamber is used to test the noise levels attained by each machine in their range. There are tough noise regulations and standards to adhere to and the aim is to be even quieter than these, then to continually improve on what's been achieved. We also stand to benefit - wouldn't it be bliss on summer Sundays when everyone's mowing their lawns with quiet machines!

One of the members of our group found it quite hard to take in there because they suffer from tinnitus. The sounds of ordinary life can help people cope with the condition and they were removed completely in this room. You can get a good idea of what that's like here.

Note that the dull sound when someone speaks isn't a fault in the recording, that's just what sound without an echo is like. NB this chamber no longer holds the world record as the quietest place on earth as mentioned in the video, that's currently held (at the time of writing) by Microsoft.

In conclusion

It was an impressive couple of days of presentations, factory tour and question/answer sessions which showcased the care Viking take to ensure their models are built to last and continually improved in their design. Of course I can't say how they compare with other manufacturers in this respect, but I came away with a much better understanding of how one company brings their products to market.

The people involved enjoy their work too, which was great to see. I also have a better insight into why NAH believes being an engineer is the best job in the world.

Disclosure: Viking were my generous hosts, whose attention to detail and pride in both their work and our entertainment shone through the whole of the trip.

Their attention to detail even extended to the cake we were given in our packed lunch on the way to the factory from Munich.

All opinions and views are my own.

You may also like:

- An hour in Munich: My Weekend Wandering post from the same trip which highlights some of the wonderful sights of central Munich. NAH and I are already planning a trip back there

- Jay's fun review of the same trip in his blog Gadgety News - he has more details of Viking's product range for you to explore there. He was also much better than me at remembering to take photos in the non-factory bits

- Stephanie's thoughts on the trip in her Life at 139a blog, and my companion on the plane home. I also enjoyed her post about her return to a snowy Hofgarten in Munich

- Emma's 3-for-the-price-of-1 blog manages to squeeze in Munich, Kufstein and the Viking factory into one post. Kudos Emma!

And finally...

I was reluctant to mention lawnmower racing when I was there as I thought it might be in bad taste. However, I've since learned Viking currently holds the world record for the fastest lawn tractor... 134mph!

If the embedded link doesn't work, try here.

The scenery is so lovely that I doubt I could have dragged myself into the factory even one as interesting.

ReplyDeleteIn my previous life as am IT consultant for primary schools we were often given new software to review before it was released and we used to pick it to crashing point too. We would be presented with all singing applications. When the developer returned we would come up with can it do x, y and z and the developer would reply "so it looks like we still have work to do" and go away disappointed. They said at least they knew if we said it was good - it was!

There are plenty of windows (as they like to utilise natural light as much as possible), so it's possible to see outside even from the factory floor. That was one of the unusual aspects of the factory I'd forgotten about, so thanks for the reminder Sue :)

DeleteNot being a mechanical person, I'm not sure how much I would have enjoyed the factory visit--I would have gladly stayed outside and enjoyed the scenery instead! My husband, on the other hand, would love the racing lawnmower--we have a big yard:)

ReplyDeleteInteresting Rose... I'm not mechanical either but I've loved factory visits ever since I took a term's course of visits at school many years ago. I love understanding what makes a company tick and understanding what they do (or would like to do). I thought I'd be the only person there with that kind of fascination, but it turned out pretty much everyone was excited at the prospect of a factory tour, especially the testing bit :)

Delete